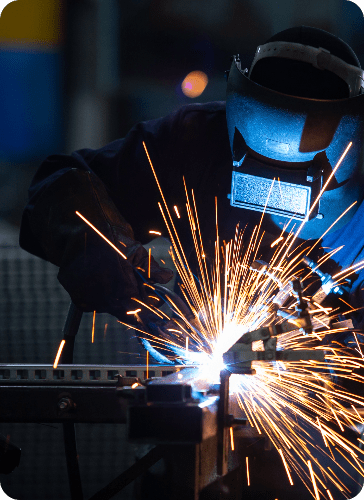

Fabrication

Connect Group’s full-service engineering, drafting and fabrication teams work closely together to provide an integrated value-added model. When introduced at the onset of fabrication and execution project planning, our full-service engineering and drafting division adds significant project value, optimizing constructability and lowering project costs while facilitating adherence to project schedules.

Connect Group manages intentional partnerships with a select group of like-minded fabricators across Canada. This access to capacity gives us the ability to address changes in project scope and schedule

FABRICATION HIGHLIGHTS

- Over 13,000 sq/ft of fabrication space

- 12 fabrication stations with welding processes covering SMAW/FCAW/MCAW & GTAW for Carbon & Stainless

- ABSA Certified Quality Management Manual

- AQP-22065 for B31.3 Shop & Field fabrication and erection, new manual editions in 2022 to include B31.1 (BEP & NBEP), B149.1

- Structural Quality Manual developed in accordance with ISO-9001

- Extensive CWB WPS/WPDS and ASME WPS library of procedures to cover all your project welding requirements

- Connection Design, Constructability and Early Involvement Engineering

- Structural Steel Fabrication

- Pipe Spool Fabrication

- Structural & miscellaneous steel, Piping, Electrical and Equipment Assembly

- Heavy plate work, industrial process equipment, material handling equipment, large span trusses, etc.

- High-performance primary processing - Beam Line / Angle Line / Plate Line with leading-edge capabilities that exceed industry norms

- Secondary processing capabilities include our Hydmech S-20 Band Saw, Gika 110

- Ironworker and our Hypertherm 85/105

- Other Secondary Services Include: sandblasting, fireproofing, galvanizing and coating solutions; cladding, hydro testing, heat tracing, insulation, painting, spray foam, etc.

OUR CAPACITY

Shop size: 14 938 sq. ft. (1392 sq m)

Welding stations: up to 12 per shift

Rail unloading and loading capability

EXPERTISE

Shielded metal arc welding (SMAW)

Flux-cored arc welding (FCAW)

Metal Cored Arc Welding (MCAW)

STEEL GRADES

Carbon steel CAT 4

Stainless steel (304, 316 and 321)

OUR FABRICATION FACILITY IS EQUIPPED WITH AUTOMATED DETAIL EQUIPMENT THAT TRANSFERS DESIGN DATA DIRECTLY FROM OUR STEEL PROJECTS DRAFTING SOFTWARE INTO PROGRAMS FOR OUR FICEP CNC MACHINES.